- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Warehouse Automation

- Industrial Conveyor Systems

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

- D-Tools

- Careers

- Chat Live

- Blog

- Literature & Manuals

- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Rotating Conveyors

- Industrial Conveyor Systems

- Warehouse Automation

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

Material Handling Conveyors

Transforming Material Handling Through Precision Conveyor Technology

Dorner’s material handling & industrial conveyors are designed to handle all stages of the manufacturing process, from production and assembly through inspection and packing.

Material Handling Solutions from Dorner

With an array of models available, you’ll find a conveyor belt material handling solution for a range of applications – from small components and large boxes to straight or curved paths, at ground level or overhead. In addition to our standard conveyor offerings, Dorner offers custom material handling and industrial conveyor solutions designed for your unique space and business needs.

Dorner’s comprehensive range of industrial conveyors addresses the full spectrum of material handling needs, from lightweight component transport to heavy-duty bulk materials movement. Our systems integrate seamlessly with existing equipment while offering the flexibility to adapt as your requirements evolve. Whether you’re handling raw materials, work-in-process inventory, or finished goods, our precision-engineered conveyor solutions maximize efficiency at every stage of your material handling process.

Benefits of Integrating Dorner’s Material Handling Conveying Solutions

Material handling and industrial conveyors are designed to transport products through a facility or production process while maintaining a reduced footprint and improving your bottom line. Dorner’s conveyor solutions provide the following advantages:

Maximize Space

Conveyors like the FlexMove, which is designed for tight spaces, can benefit your bottom line by increasing your production capacity even with limited space.

Increase Uptime

With an automated material handling and industrial solution from Dorner’s complete line of industrial fabric belt, modular belt, and flexible chain conveyors in place, your business can speed up cumbersome processes and improve output.

Improve Efficiency and Accuracy

Dorner’s industrial conveyors are designed to handle accurate sorting, measuring, scanning, and packing of products with ease. Our solutions are reliable, fast, and can be used in a wide range of industries. With the increased accuracy of automation, you’ll improve cost efficiency and reduce waste, as well.

Lower Production and Labor Costs

Integrating an industrial conveyor system allows you to reallocate your employees from repetitive tasks to higher-priority ones, saving your business time, money, and resources.

Boost Worker Safety

Material handling machinery like industrial conveyors also improve workplace safety in a number of ways. Reducing or eliminating the need for lift trucks, for example, lessens the chance for collisions or accidents on the floor. Our systems reduce the need for manual operations and help relieve operator fatigue from heavy lifting or repetitive tasks, preventing injuries and improving morale.

Maximize Space

Increase Uptime

With an automated material handling and industrial solution from Dorner’s complete line of industrial fabric belt, modular belt, and flexible chain conveyors in place, your business can speed up cumbersome processes and improve output.

Improve Efficiency and Accuracy

Dorner’s industrial conveyors are designed to handle accurate sorting, measuring, scanning and packing of products with ease. Our solutions are reliable, fast and can be used in a wide range of industries.

With the increased accuracy of automation, you’ll improve cost efficiency and reduce waste, as well.

Lower Production and Labor Costs

Integrating an industrial conveyor system allows you to reallocate your employees from repetitive tasks to higher-priority ones, saving your business time, money, and resources.

Boost Worker Safety

Material handling machinery like industrial conveyors also improve workplace safety in a number of ways.

Reducing or eliminating the need for lift trucks, for example, lessens the chance for collisions or accidents on the floor. Our systems reduce the need for manual operations and help relieve operator fatigue from heavy lifting or repetitive tasks, preventing injuries and improving morale.

Distribution Center Mainline Conveyors

Conveyors are an essential part of any successful warehousing operation and can greatly reduce labor costs and increase efficiency. Warehousing and distribution center applications for conveyor systems range from simple package handling, to complex sorting and order fulfillment operations.

The DCMove conveyor from Dorner, for example, is designed with a low profile that allows them to fit easily into tight spaces, maximizing your available space without reducing belt coverage. With a high load capacity of 400 lbs., the DCMove is a great choice for conveying packages and other heavy items.

Accumulation

Material flow conveyor systems are ideal for applications where product queues need to be maintained in order to control production flow. You can use conveyors to hold products in place until they are needed, while also allowing sufficient product spacing to facilitate proper sorting.

Sortation

Integrate conveyors into your warehouse sorting system to quickly and efficiently move products from one station to another. This can be done using powered or gravity-based conveyors, as well as a combination of both in order to create more complex sorting operations.

Transportation

With transportation conveyors, you can easily move loads, large or small, along a defined path in your warehouse. These systems are perfect for moving items from one side of the facility to another and ensuring that they arrive safely and on time.

Storage & Retrieval

Using an industrial conveyor system, you can greatly enhance your storage and retrieval processes. Automated storage and retrieval systems allow efficient access to stored items while also preventing product damage, and industrial conveyors can be used to control product flow and optimize the system as needed.

AMR conveyors, for example, can be used to automate the storage and retrieval of products in warehouses and distribution centers, reducing the need for physically-demanding manual labor from the equation. This type of system also reduces the amount of space needed for product storage and increases efficiency by accurately placing items exactly where they need to be.

Printing and Packaging

Conveyor systems are also well-suited to printing and packaging applications where precise product placement is important. With the right conveyor configurations, you can combine the flexibility of manual operations with efficient automated processes to improve production speeds and reduce labor costs.

The DCMove conveyor system is well-suited for printing and packaging applications, allowing you to move packages of all sizes quickly, efficiently, and safely.

Product Handling

Material handling industrial conveyors are a great way to increase the efficiency of product handling processes. From palletizing and depalletizing, to sorting and assembly line operations, our conveyor systems can be customized to fit any application.

Inspection

Integrate conveyors into your inspection, testing, and quality control processes with industrial grade systems that can handle even the most demanding workloads, allowing for quick corrective action and improved product quality.

Dorner’s Industrial Conveyor Systems for Material Handling

Dorner is one of the leading material handling equipment manufacturers in the world, offering a full line of industrial conveyor systems suitable for material handling applications. Our reliable, high-quality solutions are designed to improve efficiency, maximize space, and increase uptime in material handling operations.

DCMove

Our newest model, the DCMove belted conveyor, is ideally suited for material handling and storage applications. With a high-friction PVC belt option for added durability, combined with our v-guided belt tracking, the DCMove is designed for a range of industrial applications, including material handling, printing and labeling, packaging, palletizing, and more.

2700 Series

Designed with a higher load capacity and increased maximum width, our 2700 Medium Duty conveyors feature precision belt tracking and a small footprint, making them suitable for a range of applications, including integration with AMRs or AGVs for optimal efficiency and improved material handling ergonomics, reducing the strain on workers.

2200 Series

Dorner’s 2200 Series Conveyors are a great solution for small- to medium-part handling, transfers, accumulation, positioning, and automated or manual assembly. They are perfect for assembly lines, packaging, and high-speed production processes.

3200 Series

The 3200 Series Conveyor Systems are suited for heavy-duty applications where the 2200 would otherwise be too small. They also handle high speeds, long runs, and mainline packaging. Both the 2200 and 3200 high-performance series offer belted, modular belt, and precision move models.

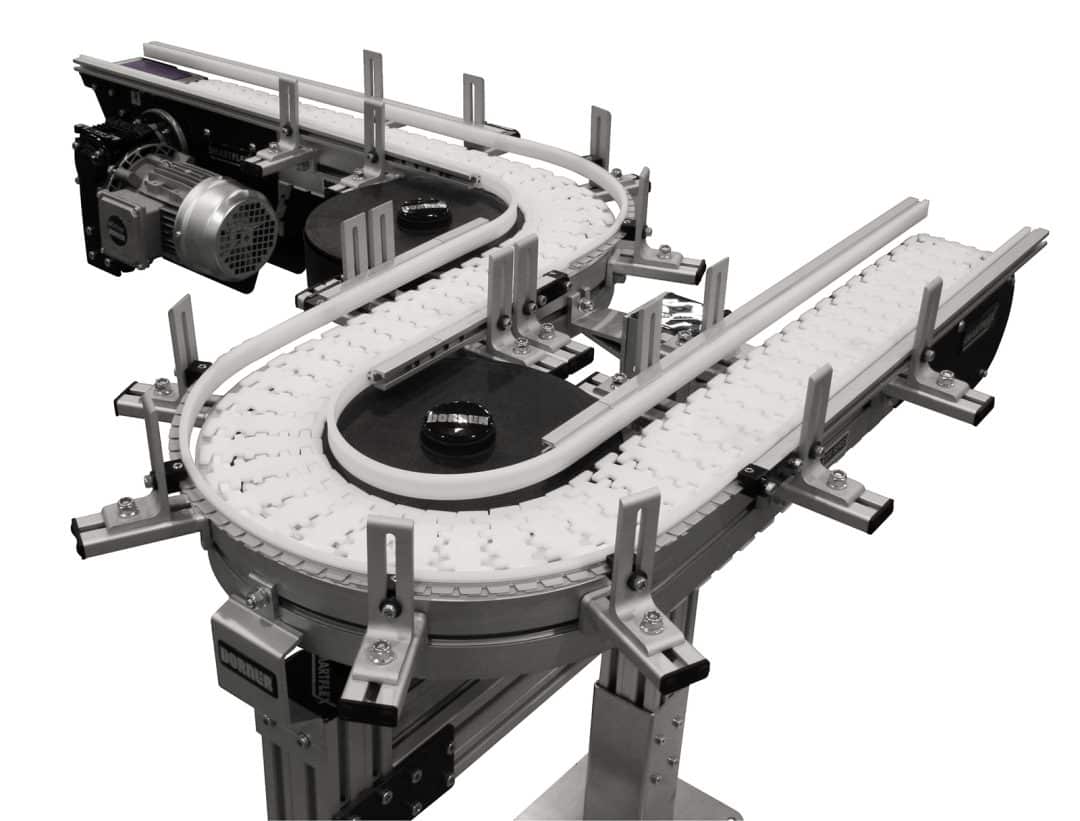

FlexMove

FlexMove conveyors are a customizable solution designed for tight spaces while still offering the flexibility to grow along with your needs. This series of material handling and industrial equipment can handle twists, multiple curves, inclines and declines on a single conveyor. FlexMove conveyors’ low-profile frame and small drive spindles also make it an ideal solution to move products as small as 3 inches in diameter.

Material Handling Challenges Solved by Dorner Conveyors

Conveyors improve efficiency, increase output, reduce costs, and, in general, keep things running smoothly. However, modern operations face specific challenges that require targeted solutions. Here’s how Dorner addresses the most critical material handling pain points:

Space Optimization

Challenge: Limited floor space constrains operational growth and efficiency.

Solution: Dorner’s low-profile designs, vertical solutions like the FlexMove Helix, and flexible configurations maximize cubic space utilization while minimizing footprint. Our 2200 Series conveyors offer industry-leading low profiles starting at just 1.85″ height, allowing integration in tight spaces where conventional conveyors cannot fit. The FlexMove Alpine and Helix configurations create multi-level transport paths that utilize vertical space efficiently, increasing conveying distance without expanding floor space requirements.

Throughput Bottlenecks

Challenge: Slow material movement and product flow interruptions create production bottlenecks.

Solution: High-speed conveyor options capable of 600 FPM (feet per minute) with precision tracking ensure continuous product flow, while our accumulation solutions like the Garvey Infinity™ tables provide zero-pressure buffering to maintain line efficiency during downstream interruptions. The patented slowdown lane technology in our accumulation tables de-nests products before they reach pickoff points, reducing turbulence and allowing processors to increase overall line speeds by up to 300%. By implementing strategic accumulation zones, our customers typically realize a 20-30% increase in overall line throughput.

Product Damage

Challenge: Conventional conveying methods can damage sensitive products through impact, abrasion, or excessive pressure.

Solution: Our patented pressureless loop technology eliminates backpressure damage, while specialized belt materials and surfaces provide optimal product handling for everything from delicate components to heavy industrial parts. The Infinity™ line of accumulation tables utilizes patented technology that allows for high-speed accumulation while eliminating damaging product collisions. For sensitive electronic components or precision-manufactured parts, our fabric belt options include anti-static materials and specialized textures that provide secure transport without marking or scratching.

System Integration Complexity

Challenge: Integrating conveyors with existing equipment and control systems often creates compatibility issues and implementation delays.

Solution: Universal T-slots, compatibility with industry-standard PLCs through our Controls Solutions partnership with Magnetek, and purpose-built modules simplify integration into existing production lines. Our conveyor systems feature standardized connections and mounting options that facilitate seamless integration with upstream and downstream equipment. The Controls Solutions team provides turnkey automation packages with dedicated project management from design through implementation, ensuring smooth integration with existing production systems while minimizing downtime during installation.

Maintenance Downtime

Challenge: Excessive maintenance requirements cause production interruptions and increase operational costs.

Solution: V-guided belting for consistent tracking, precision rack-and-pinion tensioning, and belt life indicators minimize maintenance needs and unplanned downtime. Our industry-leading 10-year warranty reflects our confidence in conveyor longevity. Dorner’s belt tracking system outperforms competitors by applying V-guiding before splicing rather than after, creating a seamless guide that improves accuracy and eliminates potential failure points. Finally, our preventative maintenance programs aim to identify potential issues before they impact production, reducing unplanned downtime by up to 80% compared to reactive maintenance approaches.

Labor Efficiency

Challenge: Labor shortages and rising costs make manual material handling increasingly unsustainable.

Solution: Dorner’s automated conveyor systems reduce labor requirements while improving ergonomics for remaining staff. Our pallet system conveyors like the DualMove facilitate precision product positioning for automated processing, while accumulation solutions eliminate the need for manual product staging between processes. By automating routine material transport tasks, companies typically realize labor efficiency improvements of 40-60% while reducing workplace injuries related to manual handling by as much as 80%.

Changing Production Requirements

Challenge: Evolving product mixes and production schedules require flexible material handling systems that can adapt quickly.

Solution: Modular conveyor designs offer exceptional adaptability, allowing manufacturers to handle a wide range of product sizes and materials on a single system. Features such as adjustable guiding, integrated T-slots along the entire conveyor length for easy accessory adjustments, and programmable product flow controls support quick changes in production requirements. Additionally, our DTools configurator simplifies the initial system design process, enabling customers to efficiently visualize and implement layout adjustments. This flexibility helps manufacturers respond to market demands without the capital expense of entirely new conveyor systems.

Conveyor Advantages for Material Handling

Dorner offers a variety of material handling conveyors to meet your specific needs. Our industrial handling conveyor systems include the following key benefits:

- Increased productivity and throughput

- Improved ergonomics and workplace safety

- Reduced labor costs through automation

- Enhanced product quality and consistency

- Optimized floor space utilization

- Adaptability to changing production requirements

- Seamless integration with existing equipment

As material handling and industrial conveyors transport products through a facility or production process, they reduce footprint and improve your bottom line. With an automated material handling and industrial solution from Dorner’s complete line of industrial fabric belt, modular belt, and flexible chain conveyors in place, your business can speed up cumbersome processes and improve output.

Dorner’s industrial conveyors are designed to handle accurate sorting, measuring, scanning and packing of products with ease. Our solutions are reliable, fast and can be used in a wide range of industries. With the increased accuracy of automation, you’ll improve cost efficiency and reduce waste, as well.

Material Handling Applications Transformed by Conveyor Technology

When it comes to warehouse material handling equipment, Dorner conveyors offer a variety of solutions to help you get the job done quickly and efficiently. Whether you’re looking for an economical system to move boxes in bulk or need custom material handling solutions that can handle delicate parts, our conveyors provide smooth, precise movement and make it easy for your team members to keep up with orders.

Like our conveyors, lift systems and material handling equipment are suitable for a range of sophisticated applications:

Automated Sortation

Modern distribution centers leverage intelligent conveyor systems to automate the sortation process, reducing labor costs while increasing accuracy. Dorner’s precision move conveyors provide exact positioning for barcode scanning and automated routing, while diverter and pusher modules enable high-speed sortation without manual intervention. Our 3200 Series conveyors with integrated diverter technologies can accurately sort up to 150 packages per minute, with positioning accuracy within ±0.02 inches.

The key to effective automated sortation lies in the seamless coordination between scanning systems, control software, and physical diversion mechanisms. Dorner’s Engineered Solutions team collaborates with system integrators to develop customized sortation systems that maximize throughput while maintaining gentle product handling. For e-commerce fulfillment centers processing thousands of orders daily, these systems have demonstrated accuracy rates exceeding 99.8% while reducing labor requirements by up to 60%.

Cross-Docking Operations

In cross-docking facilities where speed is critical, our DCMove heavy-duty, painted steel frame conveyors provide the robust performance needed for rapid transfer between receiving and shipping areas, handling loads up to 75 lbs/ft at speeds up to 600 FPM. The economic painted steel frame design offers an excellent balance of durability and value, while the internal motor mounting reduces the conveyor’s footprint and simplifies integration into tight loading dock environments.

Cross-docking efficiency depends on minimizing product dwell time and maximizing throughput. Dorner’s conveyor systems create continuous flow paths that reduce manual handling points while maintaining product orientation and integrity. By implementing strategic accumulation zones with Garvey’s Infinity™ or Bi-Flo™ tables, cross-docking operations can effectively buffer incoming shipments and synchronize outbound loading, reducing dock-to-dock cycle times by up to 40%.

Robotic Pick-and-Place Integration

The precision and repeatability of Dorner’s 2200 Series and DualMove pallet systems make them ideal platforms for robotic pick-and-place operations. With positioning accuracy within ±0.02″, these systems ensure consistent product presentation to robotic cells, maximizing automation efficiency. The DualMove’s timing belt-driven pallets provide definitive product positioning, while the system’s modular design allows for flexible cell configurations.

Effective robotic integration requires more than just precise positioning—it demands seamless communication between conveyor controls and robotic systems. Through our partnership with Magnetek, we provide comprehensive control solutions that coordinate conveyor movement with robotic actions, optimizing cycle times and minimizing “wait states.” For electronics assembly operations and medical device manufacturing, these integrated systems have achieved throughput improvements of 25-40% compared to conventional approaches.

Parts Handling in Manufacturing

For manufacturing environments dealing with metal, plastic, or composite parts, our 3200 Series Heavy Duty conveyors provide the durability needed for continuous operation, with load capacities up to 1,000 lbs and the flexibility to create complex handling systems with curves and elevation changes. The robust design includes reinforced frames, large diameter rollers, and industrial-grade bearings for reliable and consistent operation in demanding 24/7 productions.

Parts handling applications often require specialized belt surfaces to accommodate unique product characteristics. Dorner offers an extensive range of belt materials and textures, from high-friction surfaces for inclined transport to perforated belts for cooling operations. For metalworking applications where chips, oils, and coolants are present, our belting options include oil-resistant materials and designs that prevent debris accumulation while facilitating easy cleaning.

Accumulation and Buffering

Material flow conveyor systems are ideal for applications where product queues need to be maintained in order to control production flow. Our Garvey Infinity™ and Bi-Flo™ accumulation systems create efficient buffering zones that maintain line efficiency during downstream stoppages or speed variations, eliminating up to 30% of downtime in typical production environments. Unlike conventional accumulation conveyors that create damaging backpressure, Dorner’s patented technology enables zero-pressure accumulation even at high speeds.

The strategic placement of accumulation zones throughout a production facility acts as insurance against the inevitable variability in process times and equipment performance. Our expert team conducts comprehensive line analyses to identify optimal accumulation points and capacities, ensuring maximum operational efficiency. For food processing operations with varying cook times or packaging equipment that requires periodic adjustments, these systems have demonstrated payback periods as short as 3-6 months through increased overall line efficiency.

E-Commerce Order Fulfillment

The booming e-commerce sector demands high-throughput, flexible conveying solutions that can handle diverse product types while maintaining accuracy and gentle handling. Our modular systems adapt to changing business needs, accommodating seasonal volume fluctuations while ensuring efficient product flow from picking through packing and shipping.

E-commerce fulfillment centers face unique challenges, including wide variations in product sizes, weights, and handling characteristics. Dorner’s conveyor systems can be configured with multiple belt types and specialized modules to create optimized handling paths for different product categories. By implementing zone-based conveying strategies with appropriate accumulation points, e-commerce operations can balance workloads across picking and packing stations, increasing throughput by 30-50% during peak demand periods without corresponding increases in labor.

Vertical Transportation

Maximizing cubic space utilization is critical in facilities with limited floor space. Dorner’s FlexMove Helix and Alpine conveyors provide efficient vertical transport solutions that connect multiple levels while maintaining a minimal footprint. The helical design creates a smooth transition between elevations, preserving product orientation and preventing tipping or sliding.

Vertical conveying applications require careful consideration of product stability, belt selection, and drive power. Our engineering team analyzes these factors to design systems that reliably transport products between levels without compromising speed or handling quality. For distribution centers seeking to expand capacity within existing buildings, these vertical solutions have enabled throughput increases of 35-50% without facility expansion.

Warehousing and Distribution

Conveyors are an essential part of any successful warehousing operation and can greatly reduce labor costs and increase efficiency. Warehousing and distribution center applications for conveyor systems range from simple package handling, to complex sorting and order fulfillment operations.

The DCMove conveyor from Dorner, for example, is designed with a low profile that allows it to fit easily into tight spaces, maximizing your available space without reducing belt coverage. With a high load capacity of 400 lbs., the DCMove is a great choice for conveying packages and other heavy items.

You can use conveyors to hold products in place until they are needed, while also allowing sufficient product spacing to facilitate proper sorting. Integrate conveyors into your warehouse sorting system to quickly and efficiently move products from one station to another. This can be done using powered or gravity-based conveyors, as well as a combination of both in order to create more complex sorting operations.

With transportation conveyors, you can easily move loads, large or small, along a defined path in your warehouse. These systems are perfect for moving items from one side of the facility to another and ensuring that they arrive safely and on time.

Automated Storage and Retrieval

Using an industrial conveyor system, you can greatly enhance your storage and retrieval processes. Automated storage and retrieval systems allow efficient access to stored items while also preventing product damage, and industrial conveyors can be used to control product flow and optimize the system as needed.

AMR conveyors, for example, can be used to automate the storage and retrieval of products in warehouses and distribution centers, reducing the need for physically-demanding manual labor from the equation. This type of system also reduces the amount of space needed for product storage and increases efficiency by accurately placing items exactly where they need to be.

Learn More About AMR Conveyors

Printing and Packaging

Conveyor systems are also well-suited to printing and packaging applications where precise product placement is important. With the right conveyor configurations, you can combine the flexibility of manual operations with efficient automated processes to improve production speeds and reduce labor costs.

The DCMove conveyor system is well-suited for printing and packaging applications, allowing you to move packages of all sizes quickly, efficiently, and safely.

Inspection and Quality Control

Material handling industrial conveyors are a great way to increase the efficiency of product handling processes. From palletizing and depalletizing to sorting and assembly line operations, our conveyor systems can be customized to fit any application.

Integrate conveyors into your inspection, testing, and quality control processes with industrial grade systems that can handle even the most demanding workloads, allowing for quick corrective action and improved product quality.

Work-In-Process (WIP) Management

Effective WIP management balances production flow, minimizes inventory costs, and reduces floor space requirements. Dorner’s conveyor systems create dynamic WIP storage through continuous movement, replacing static racking with flowing inventory that connects production steps seamlessly. Our precision move conveyors ensure accurate placement for downstream processes, while accumulation zones provide buffering during process time variations.

By converting static WIP to dynamic flow, manufacturers typically reduce inventory levels by 15-25% while improving visibility and traceability. The continuous movement also reduces the risk of product damage associated with multiple handling points in traditional WIP management approaches. For industries with high-value components, these improvements translate directly to reduced capital requirements and improved cash flow.

Custom Material Handling Conveyors for Industrial Environments

Dorner has a wide variety of conveyors and automation components to fit any material handling needs. Our industrial grade conveyance systems can help you increase efficiency, maximize production throughput, and reduce costs.

Learn Material Handling

Lean material handling is a value-added function of material movement that seeks to reduce waste and improve productivity by optimizing material movement throughout the supply chain. It is focused on eliminating any non-value activities to increase efficiency and reduce costs in the workflow. Lean material handling relies heavily on automation and standardization, which can be aided with the integration of our conveyor systems.

Dorner’s custom material handling industrial conveyor offerings are designed and manufactured to meet your specific workflow needs. Our Engineered Solutions Groups offers an array of customizable, automated solutions to fit all stages of your process or spaces of all sizes, including:

- Customized configurations for unique spatial constraints

- Specialized belt materials for specific product requirements

- Integrated controls and automation systems

- Multi-level and multi-directional conveying systems

- Complete turnkey material handling solutions

Dorner’s expert customer service agents will ask the right questions in order to understand your business goals and challenges, and then our custom solutions team, composed of drafters, designers, and electrical and mechanical engineers, will get to work.

Custom Pharmaceutical Material Handling Solution

We worked with a pharmaceutical company that wanted to increase its efficiency. At the time, pharmacy technicians manually carried totes between their filling stations and the verification and packing stations. This was not the best use of their employees’ time.

After consulting with Dorner, the result was a three-level tote handling system that allowed prescriptions to move through the facility automatically, with operators positioned at strategic locations for optimal material handling safety and efficiency.

Our custom material handling and industrial conveyor offerings come with the same installation, training, and maintenance services as our standard lines, so you can be sure you’re getting the same quality service throughout your partnership with us no matter what type of material handling machines you choose.

Embrace Lean Material Handling With Dorner Conveyors

Dorner has a wide variety of conveyors and automation components to fit any material handling needs. Our industrial grade conveyance systems can help you increase efficiency, maximize production throughput and reduce costs.

What Is Lean Material Handling?

Lean material handling is a value added function of material movement that seeks to reduce waste and optimize productivity through a process of optimizing material movement throughout the supply chain. It is focused on eliminating any non-value activities to increase efficiency and reduce costs in the workflow. Lean material handling relies heavily on automation and standardization, which can be aided with the integration of our conveyor systems.

Custom Material Handling Conveyors for Industrial Environments

As part of our Engineered Solutions Group, Dorner’s custom material handling industrial conveyors offerings are designed and manufactured to meet your specific workflow needs. We offer an array of customizable, automated solutions to fit all stages of your process or spaces of all sizes, including:

- Inspection and testing

- Elevations and line egress

- Index and positioning

- Depositing and rejects

- Diverting and sorting

- Product flow and control

- Merging

Dorner’s expert customer service agents will ask the right questions in order to understand your business goals and challenges, and then our custom solutions team – composed of drafters, designers, and electrical and mechanical engineers – will get to work.

Custom Pharmaceutical Material Handling Solution

Curious about our process? We worked with a pharmaceutical company that wanted to increase its efficiency. At the time, pharmacy technicians manually carried totes between their filling stations and the verification and packing stations. This was not the best use of their employees’ time.

After consulting with Dorner, the result was a three-level tote handling system that allowed prescriptions to move through the facility automatically, with operators positioned at strategic locations for optimal material handling safety and efficiency.

Material Handling Conveyors Services from Dorner

Our custom material handling and industrial conveyor offerings come with the same installation, training, and maintenance services as our standard lines, so you can be sure you’re getting the same quality service throughout your partnership with us no matter what type of material handling machines you choose.

Service and Support

Installation

Dorner’s expert service team offers professional, on-site installation for our conveyor systems. With efficiency in mind and an eye for safety, our engineers handle everything from delivery and staging to set-up and maintenance training.

Whether a large-scale, custom installation or a solution for a smaller operation, we’ll get your equipment ready for optimal performance. If you enlist your internal team or hire a third-party contractor for installation, a Dorner service manager is available to supervise your crew.

Training

Our team is here to help yours. Not only does the Dorner team teach your employees how to use your business’s new system upon installation, we also offer group and one-on-one training in product care and preventative maintenance.

With an end goal of preventing and reducing downtime, our training will focus on safety, mechanical troubleshooting and parts changing.

In addition to on-site training, your team will have access to our extensive library of resources, from guides to videos.

Aftermarket Support

Dorner continues to support you throughout the life of your conveyor system. When your material handling and industrial equipment needs a new part, you can contact us for a replacement.

We also offer a parts auditing program in which one of our service team members will visit your business location, survey your system, and make a list of recommended spare parts and maintenance concerns. You can also call our service hotline 24 hours a day, seven days a week. We are open when you are.

Preventative Maintenance

Dorner offers a comprehensive Preventative Maintenance Program, with services tailored toward your needs. Available in two levels (labor or parts and labor), each program starts with a free initial site visit to evaluate your needs, followed by a customized program proposal highlighting recommended service intervals.

A few of the services included in the conveyor maintenance program include:

- Belt replacement and tracking

- Bearing inspection and lubrication

- Drive component inspection and adjustment

- Control system verification and optimization

- System cleaning and debris removal

- Comprehensive performance testing

Material handling systems offer a streamlined and safe solution for many production needs. Dorner offers custom solutions designed to meet your exact specifications, backed by an experienced team of engineers and technicians. Our tailored solutions are designed for peak efficiency and productivity, helping you maximize your output while reducing overhead costs.

Contact us today to learn more about how we can help maximize the potential of your material handling operations.

Material Handling - The Backbone of Modern Industrial Efficiency

Material handling operations are the backbone of modern industrial efficiency, with conveyor systems driving up to 300% increases in throughput compared to manual processes. As manufacturing and distribution facilities face increasing pressure to maximize productivity while minimizing labor costs, intelligent conveyor solutions have become essential infrastructure rather than optional equipment. At Dorner, we’ve spent over five decades perfecting precision conveyor technology specifically engineered to address the unique challenges of today’s material handling environments.

The material handling industry continues to evolve rapidly, with global market valuation expected to reach $215 billion by 2030. This growth is driven by increasing automation adoption, e-commerce expansion, and the ongoing need to optimize operational efficiency while addressing labor shortages. Modern material handling conveyor systems no longer simply transport products from point A to point B—they serve as critical workflow orchestrators that synchronize production, enhance throughput, and provide valuable operational data.

Frequently Asked Questions About Material Handling Conveyors

What types of conveyors are best for heavy material handling applications?

For heavy material handling applications requiring durability and high load capacity, belt conveyors with robust frames like Dorner’s 3200 Series and DCMove are ideal solutions. These conveyors feature reinforced frames, large diameter rollers, and heavy-duty bearings capable of supporting loads up to 1,000 lbs while maintaining reliability in demanding 24/7 operations. The key factors to consider when selecting a heavy-duty conveyor include not only the weight of individual products but also the accumulated load during potential line stoppages. Dorner’s 3200 Series is engineered with these scenarios in mind, offering accumulated load capacities that maintain belt integrity even when fully loaded. For applications involving sharp or abrasive materials, specialized belting options with reinforced construction provide extended service life even under challenging conditions.

How do I calculate the right conveyor width for my material handling needs?

To determine the optimal conveyor width for your application, measure your widest product and add a minimum of 2″ (50mm) for stable conveying (1″ on each side). For applications with varying product sizes or orientation changes, add 4-6″ to accommodate product movement. When using side guides, ensure the conveyor width accommodates both the product width and the space needed for guide mounting hardware.

For irregularly shaped products, consider the maximum diagonal measurement rather than just length and width. It’s also important to account for potential product overlap in accumulation areas—Dorner recommends adding 25-30% to the minimum width calculation for applications where products may contact each other during transport. Our DTools configurator can help you visualize different width options and determine the most efficient solution for your specific product mix and handling requirements.

What is the ROI timeframe for implementing automated conveyor systems in warehousing?

Most material handling conveyor systems achieve ROI within 12-24 months, depending on application complexity and labor costs. High-volume operations typically see faster returns, often in 6-12 months, through reduced labor costs, increased throughput, and decreased product damage. Dorner’s accumulation solutions have demonstrated payback periods as short as 3-6 months in lines with frequent bottlenecks.

The ROI calculation should include both direct and indirect benefits. Direct savings include labor reduction, increased throughput, and reduced product damage. Indirect benefits, which are often overlooked but equally valuable, include improved ergonomics (reducing workers’ compensation claims), enhanced quality through consistent handling, and increased operational flexibility. Dorner’s application engineers can help develop a comprehensive ROI analysis specific to your operation, accounting for all relevant factors and providing realistic payback projections based on similar implementations.

How do pallet conveyor systems differ from standard conveyors for material handling?

Pallet conveyor systems like Dorner’s DualMove precisely transport products on platforms (shuttles or pallets) through production processes, offering advantages including exact positioning (±0.02″ accuracy), product orientation maintenance, and simplified tracking and routing. Unlike standard conveyors that provide continuous product flow, pallet systems excel in applications requiring indexing, inspection, or assembly where precise positioning is critical.

Pallet systems create a repeatable presentation of products to automated equipment, improving consistency in operations like robotic pick-and-place, automated assembly, or vision inspection. The pallets themselves can be customized with product-specific fixtures that ensure consistent orientation and prevent movement during transport. Dorner’s pallet systems utilize advanced tracking methods, including RFID integration options that enable individual pallets to carry product data throughout the manufacturing process, enhancing traceability and enabling customized processing at each station. For industries with high-mix, low-volume production, pallet systems provide the flexibility to handle multiple product variants on the same line with minimal changeover time.

What maintenance schedule is recommended for high-use material handling conveyors?

For high-use material handling conveyors in 24/7 operations, implement a tiered maintenance schedule: daily visual inspections of belt tracking and tension; weekly cleaning of photoeyes and sensors; monthly lubrication of bearings and drive components; quarterly belt condition assessment; and annual comprehensive system evaluation. Dorner’s preventative maintenance programs can reduce unplanned downtime by up to 80% compared to reactive maintenance approaches.

Effective maintenance goes beyond schedules to include proper documentation and spare parts management. We recommend maintaining a digital log of all maintenance activities, including belt replacements, tension adjustments, and drive component servicing. This history helps identify patterns that may indicate underlying issues before they cause failures. For critical production lines, keeping essential spare parts on-site (particularly belts, bearings, and drive components) can significantly reduce downtime when replacements are needed. Dorner offers spare parts kits tailored to specific conveyor models and applications, ensuring you have the right components available when needed.

How can vertical space be utilized effectively with conveyor systems?

Maximize vertical space utilization with spiral and helical conveyor configurations like Dorner’s FlexMove Helix, which can transport products between multiple levels while maintaining a minimal footprint. Z-frame (incline/decline) conveyors efficiently change elevations within production lines, while Alpine conveyors create compact, serpentine paths that dramatically increase conveying distance within limited floor space.

Effective vertical conveying requires careful consideration of product stability on inclined surfaces. For smooth or rounded products, cleated belts or specialized friction surfaces prevent sliding during elevation changes. The angle of incline is another critical factor—Dorner generally recommends maximum inclines of 30° for stable products and 15-20° for less stable items, though specialized high-friction belting can allow steeper angles in some applications. Our FlexMove Wedge conveyor provides a unique solution for applications requiring a steep incline in limited space, using side-gripping technology to securely transport products at angles up to 90° while maintaining orientation.

What factors should be considered when selecting belt material for material handling conveyors?

Selecting the optimal belt material requires balancing multiple factors including product characteristics (weight, surface texture, edge properties), environmental conditions (temperature, moisture, chemical exposure), and operational requirements (speed, incline/decline angles, accumulation needs). Dorner offers extensive belt options including:

- Thermoplastic urethane (TPU) for excellent wear resistance and oil compatibility

- Polyester for high strength-to-weight ratio in dry environments

- PVC for economical general-purpose applications

- Silicone for high-temperature applications up to 350°F

- Modular plastic belting for applications requiring drainage or airflow

- Metal mesh belts for extreme temperature or heavy-duty applications

The belt surface texture is equally important—smooth surfaces maximize conveying speed but may allow product slippage on inclines, while textured surfaces provide better grip but can be more difficult to clean. For food handling and pharmaceutical applications, belt material must also meet FDA/USDA requirements and withstand sanitizing procedures. Our application engineers analyze all relevant factors to recommend the optimal belt specification for each unique application.

What are material handling conveyors?

Material handling and industrial conveyors move products from one place to another such as throughout a distribution center or through various steps in the production process. These systems are seen in a wide variety of industries, from automotive to pharmaceutical.

Conveyor belts for material handling and industrial use are suitable for a variety of applications, from part handling and packaging to assembly automation and accumulation. Although typical loads include boxes, totes, and packages, sanitary conveyors also handle food processing and packaging of edible products, even fresh fruit and raw meat.

A conveyor belt for material handling and industrial applications can come in several configurations such as vertical, horizontal or inclined and can be powered by electricity, hydraulics and even gravity. With so many options, including custom builds, there’s a solution to meet your needs, whether it’s assembly, transportation, staging, warehousing or order picking.

What is the best type of conveyor for material handling?

The best type of conveyor for your material handling application depends on a number of factors, including:

- Product characteristics (size, weight, shape, surface texture)

- Production environment (temperature, moisture, cleanliness requirements)

- Required throughput and speed

- Available space and layout constraints

- Integration requirements with existing equipment

- Future flexibility needs

At Dorner, we have a wide selection of conveyors that can be tailored to your specific needs. Our team would be happy to help determine which solution is right for you.

What are the benefits of material handling conveyor systems?

Material handling conveyors are designed to increase efficiency and reduce overhead costs. By streamlining the production process, they can help your business save time and money while reducing the need for tedious manual labor. With a properly configured system, you can expect shorter processing times, faster order fulfillment and improved customer satisfaction.

What equipment is used with material handling conveyor systems?

In addition to the conveyor itself, there are several items of material handling equipment that can be used with a conveyor system. These include:

- Robotic pick-and-place systems

- Barcode scanners and vision systems

- Weigh scales and checkweighers

- Metal detectors and quality inspection devices

- Diverters, gates, and pushers for product routing

- Labeling and printing equipment

- Accumulation tables and buffers

You can also use AMRs or AGVs to improve product flow throughout the facility. With AMR conveyors, you can increase throughput with a flexible material handling solution.

Material Handling Conveyor Systems from Dorner: Built for Peak Efficiency and Productivity

Material handling systems offer a streamlined and safe solution for many production needs. Dorner offers custom solutions designed to meet your exact specifications, backed by an experienced team of engineers and technicians. Our tailored solutions are designed for peak efficiency and productivity, helping you maximize your output while reducing overhead costs.

Contact us today to learn more about how we can help maximize the potential of your material handling operations.

Dorner - Global Headquarters

Products

Industries

Quick Links

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy